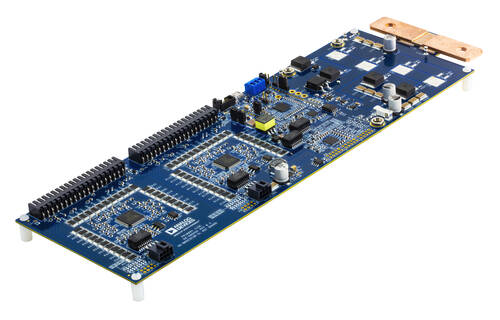

AD-BMSE2E3W-SL

72 V to 96 V Battery Management System for Electric 2- and 3-Wheelers.

A concise version of this document is available in portable document format. Click on the file below to download:

Overview

The AD-BMSE2E3W-SL is a BMS reference design for light electric vehicles (LEVs). With a voltage range of 72 V to 96 V, this solution is suitable for electric 2-wheeler and 3-wheeler vehicles with high current capacity ranging up to 100 A.

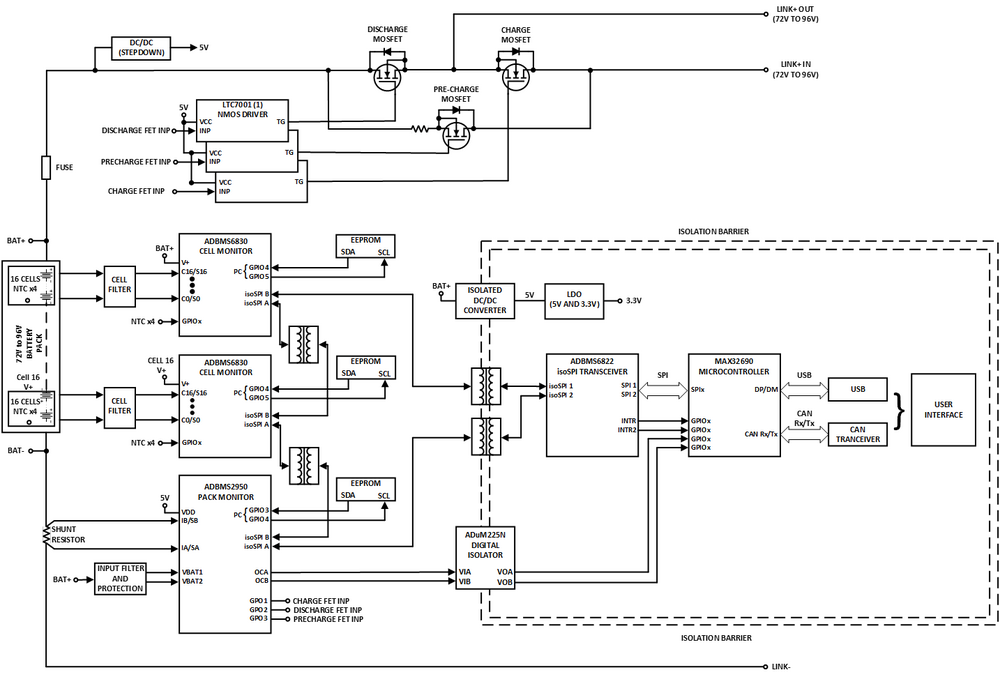

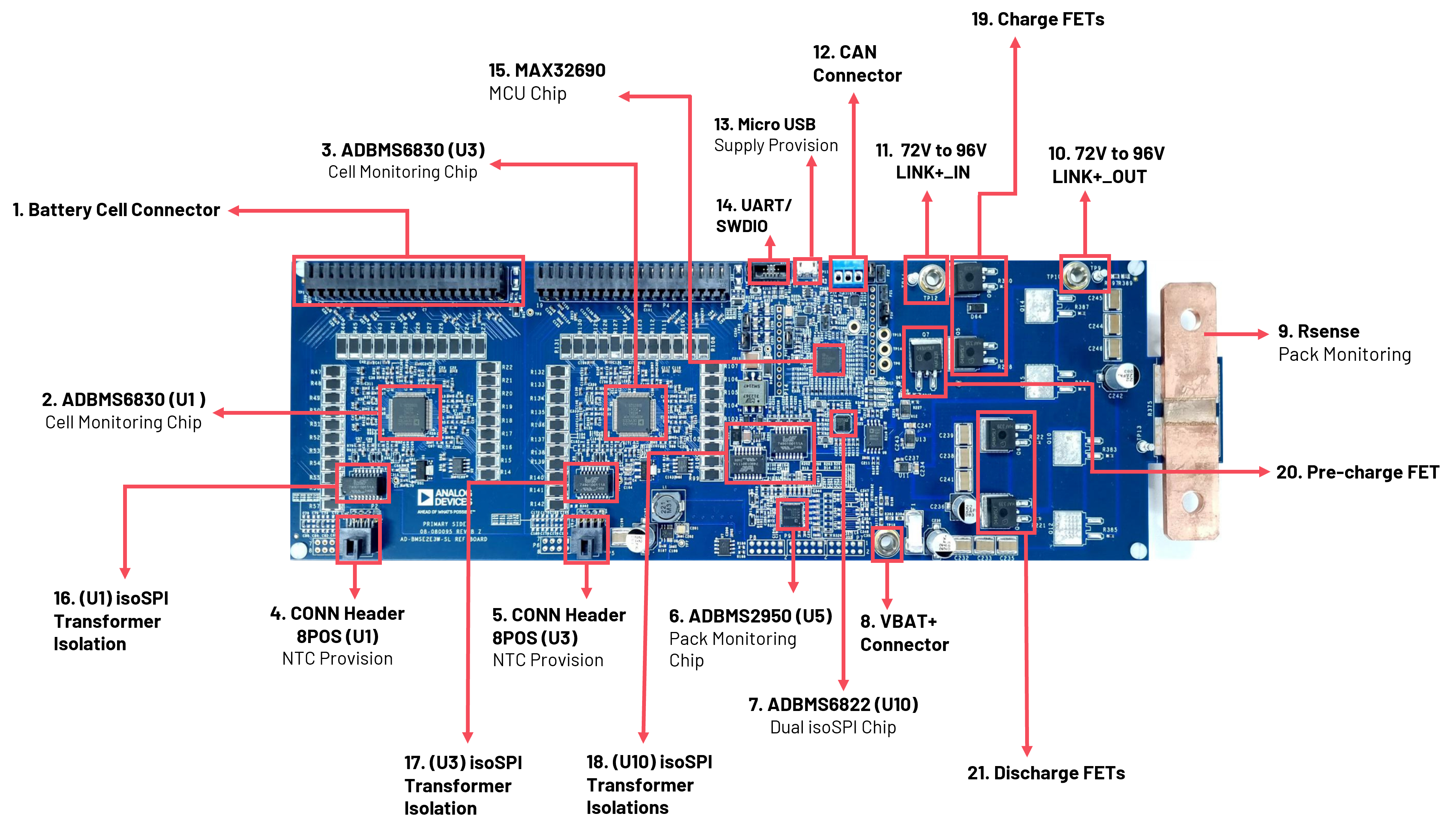

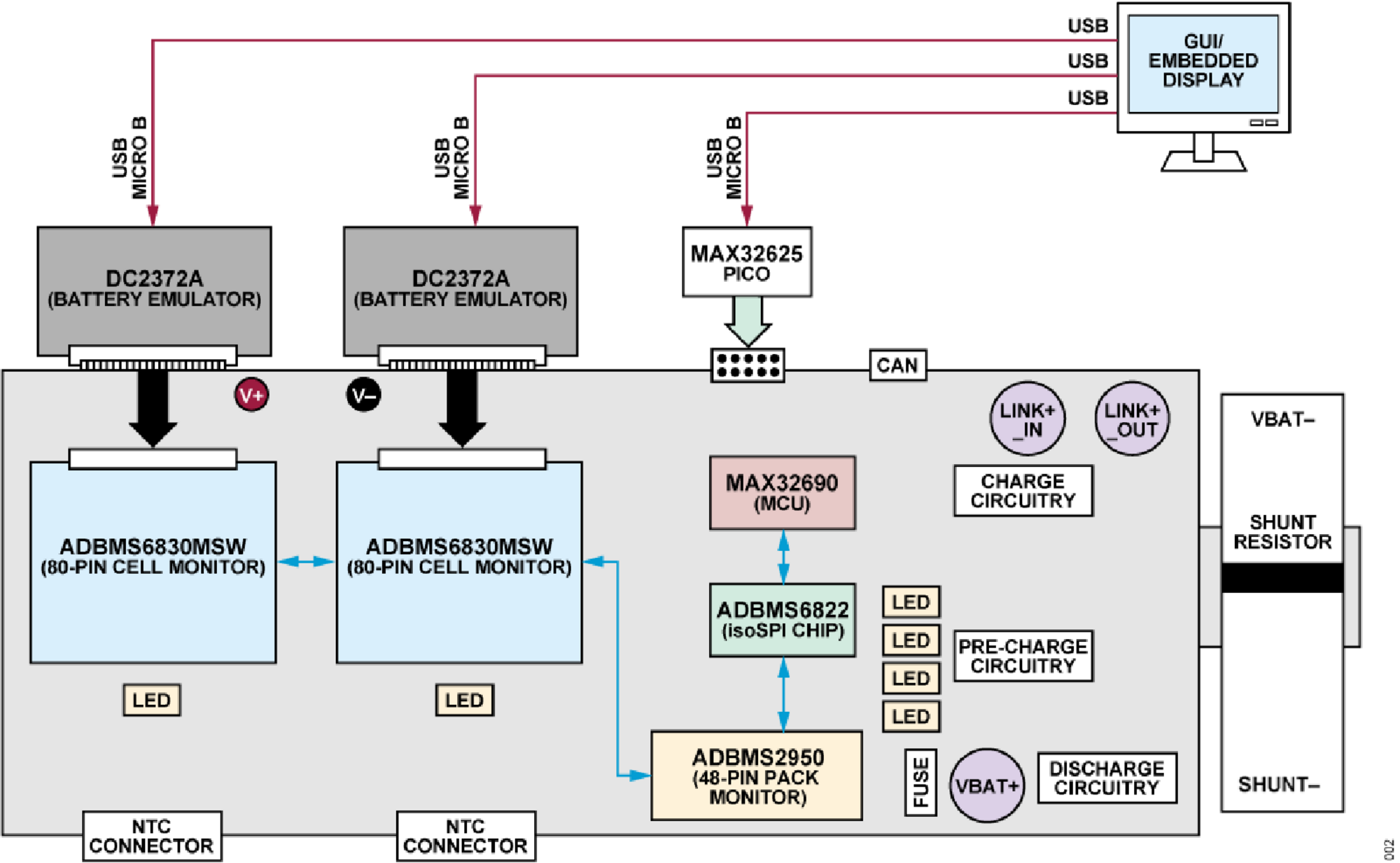

This single-board system utilizes the best-in-class ADBMS6830 cell monitoring chip that is capable of monitoring up to 2x 16-channel. This board also features battery pack monitoring using the ADBMS2950. The ADBMS6822 dual isoSPI transceiver provides a built-in 2-wire reversible isoSPI connection, which simplifies the communication of BMS parts in a daisy chain configuration before sending the data to SPI lines in the microcontroller.

The on-board MAX32690 MCU, when loaded with the firmware, can perform BMS measurements such as cell voltage (average and filtered), and pack voltage and pack current measurement. The board also has a charge, pre-charge, and discharge mode that can be controlled by the ADBMS2950 pack monitor chip.

The AD-BMSE2E3W-SL is designed to perform either in embedded mode or using a GUI, where it calculates the battery’s State of Charge (SoC) and State of Health (SoH) through enhanced coulomb counting technique.

Features

Variable 72 V to 96 V regulated voltage range, suitable for E2W/E3W applications

ASIL-D compliant and automotive grade BMS chip

Built-in charge/pre-charge, and discharge circuitry

1.8 mV total measurement error for cell voltage monitoring

High performance cell/pack voltage and current monitoring

On-board isoSPI communication

Low Power Cell Monitoring (LPCM) capability

GPIO Controllable FET Monitoring

ADBMS6830 GPIO input ready for NTC sensors

Low Power MAX32690 MCU

UART and CAN Communication

SOC and SOH through Enhanced Coulomb Counting Technique

E2W/E3W Basic System Behavior Modes

Embedded Application-ready (via CLI)

GUI capable of the following measurements and fault detection:

Cell Monitoring Voltage and Current

Pack Monitoring Charge Current Monitoring

Discharge Current Monitoring

Temperature Monitoring

Cell OV/UV Detection

Cell/GPIO Open-wire Detection

Cell Balancing

Applications

Electric and hybrid 2-wheeler vehicles

Electric and hybrid 3-wheeler vehicles

Light electric vehicles

System Architecture

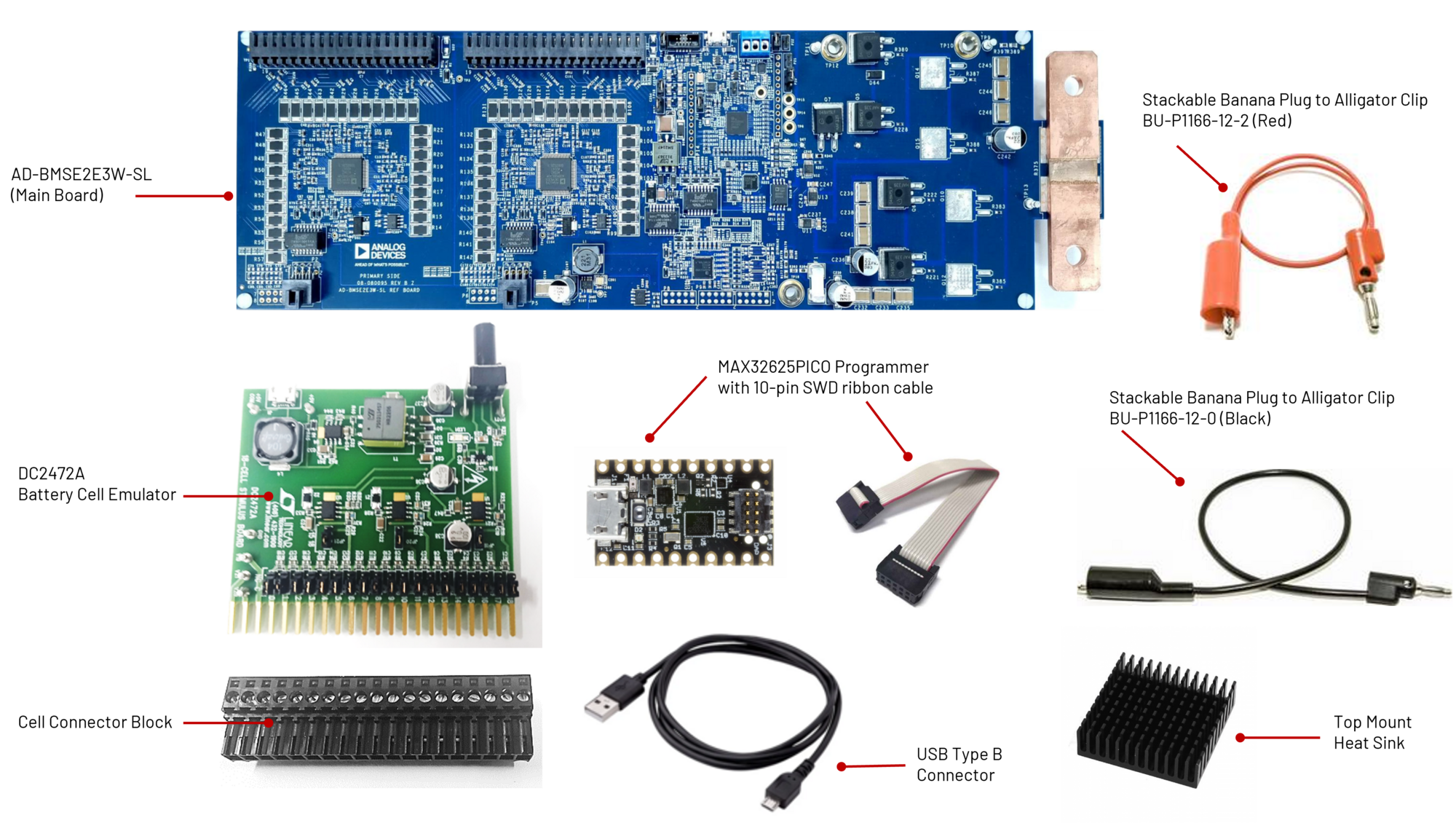

What’s Inside the Box?

Upon purchase of the AD-BMSE2E3W-SL kit, the package comes with the following boards and accessories:

Components and Connections

System Evaluation

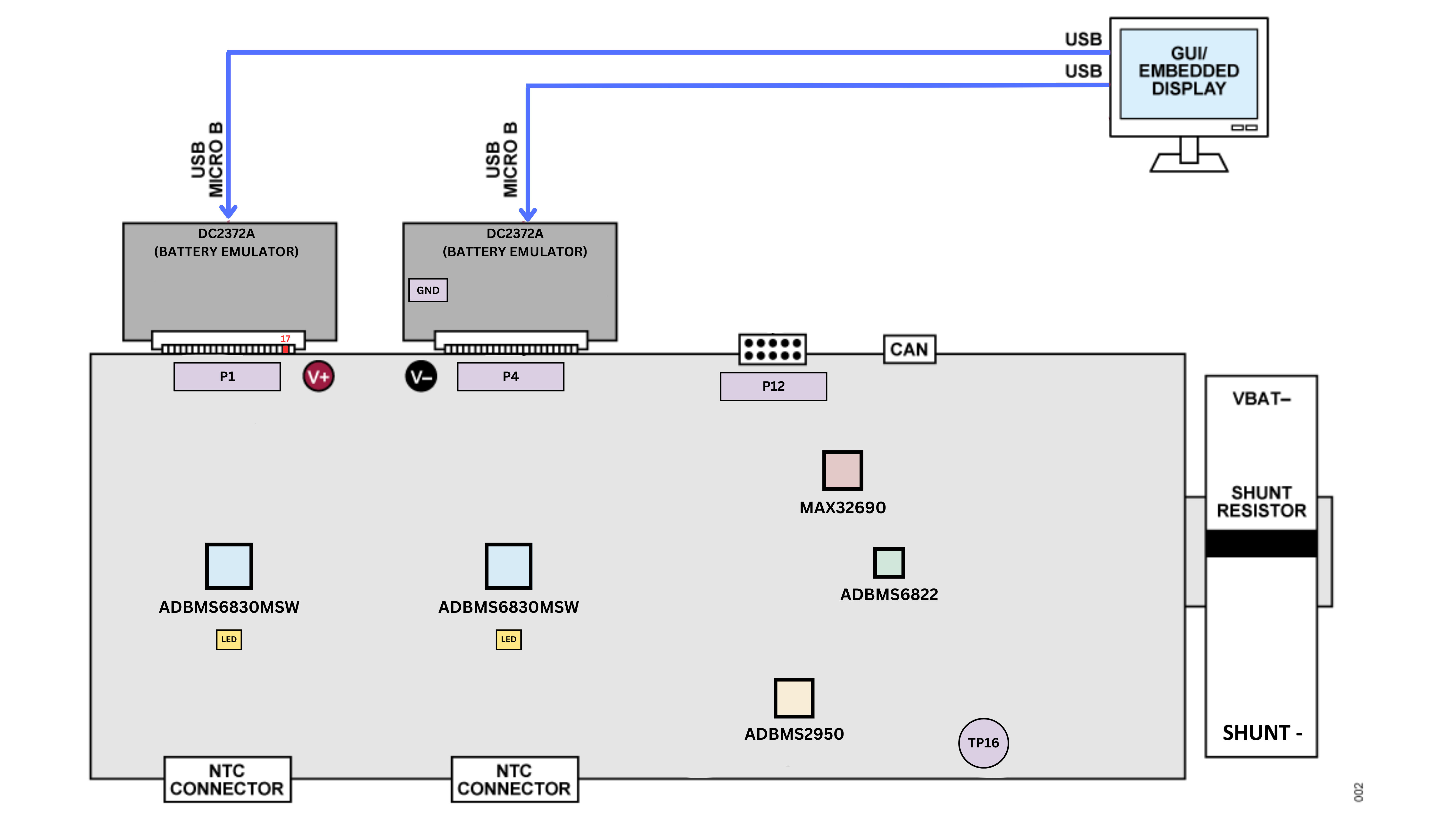

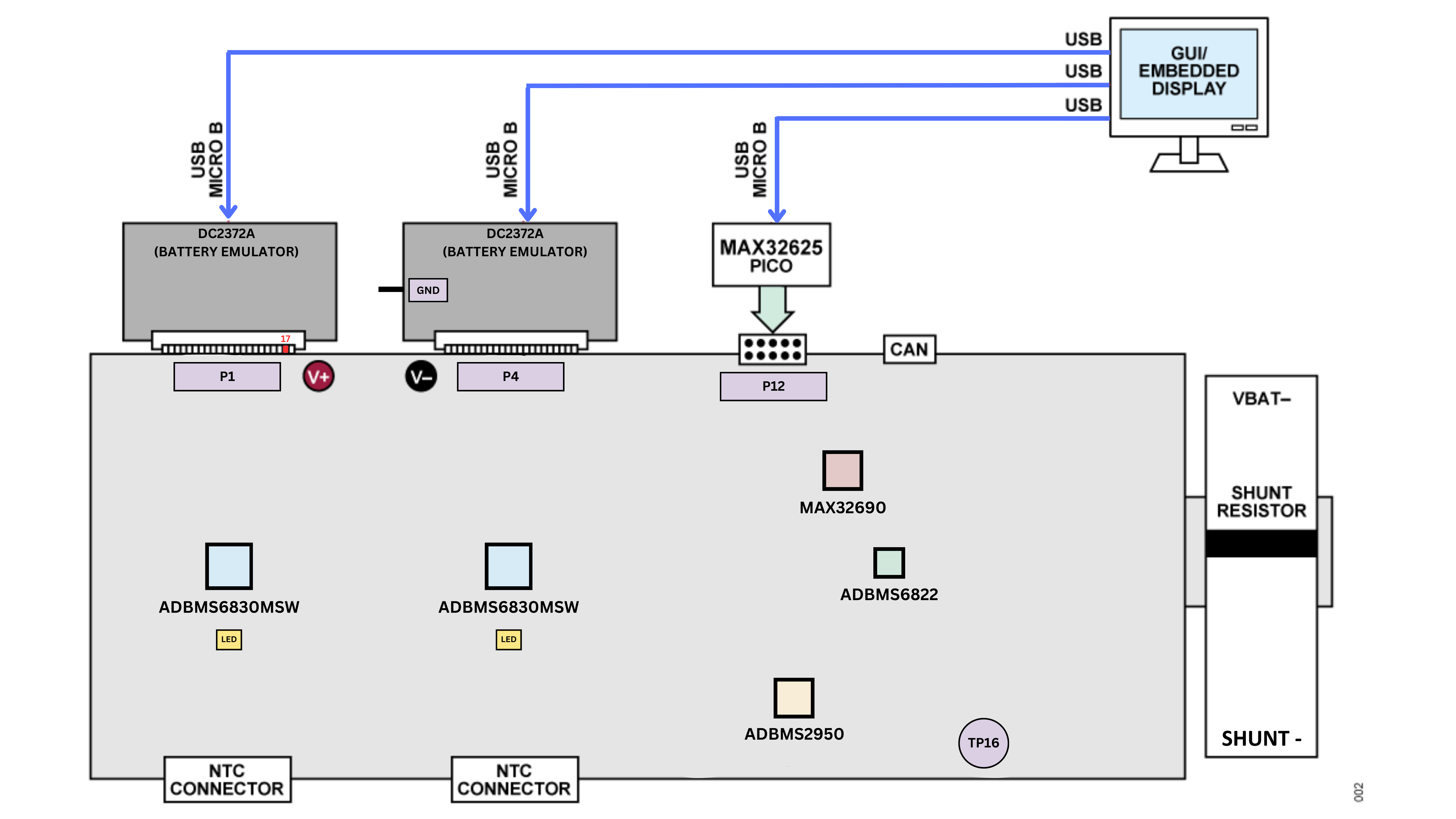

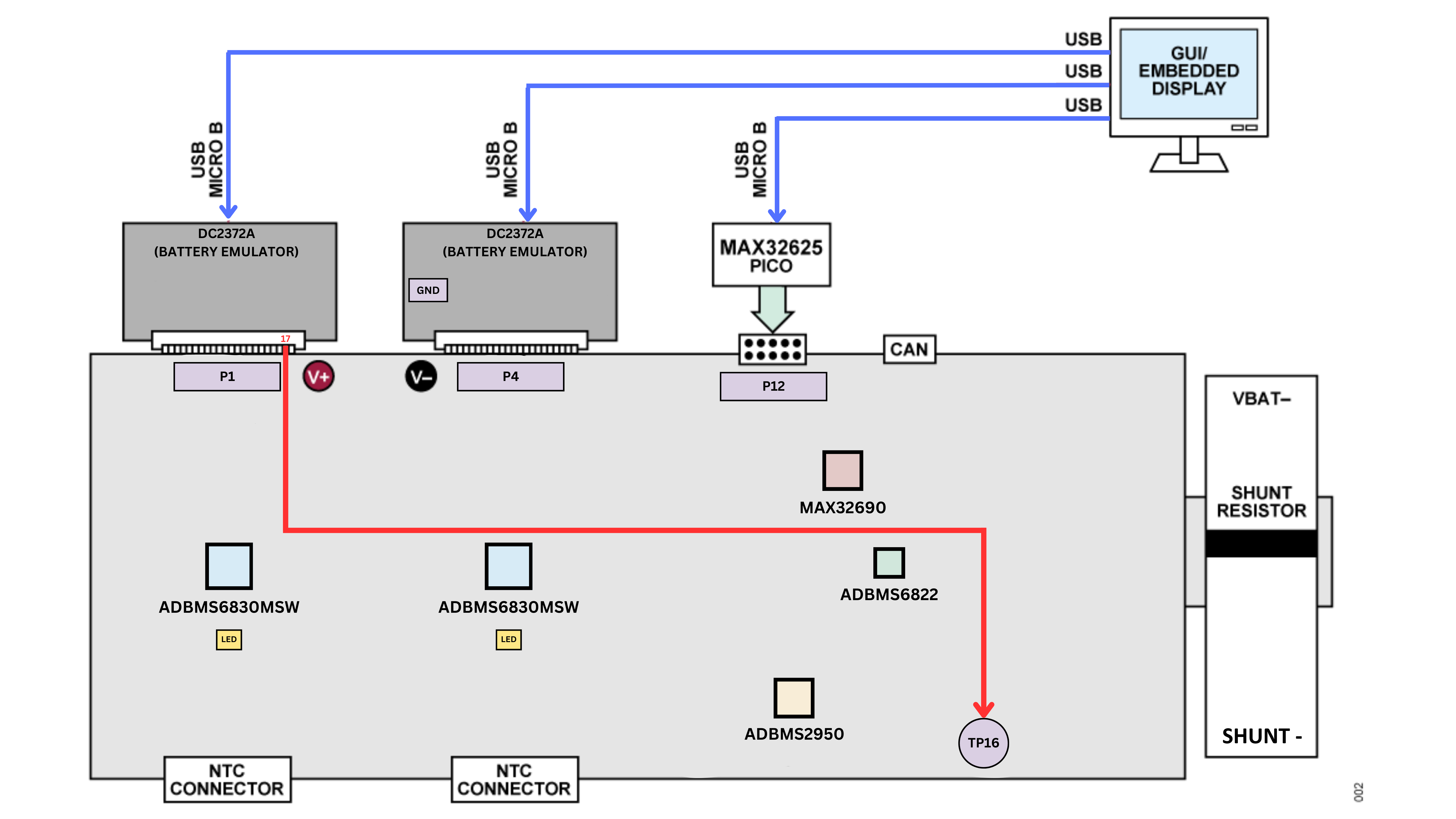

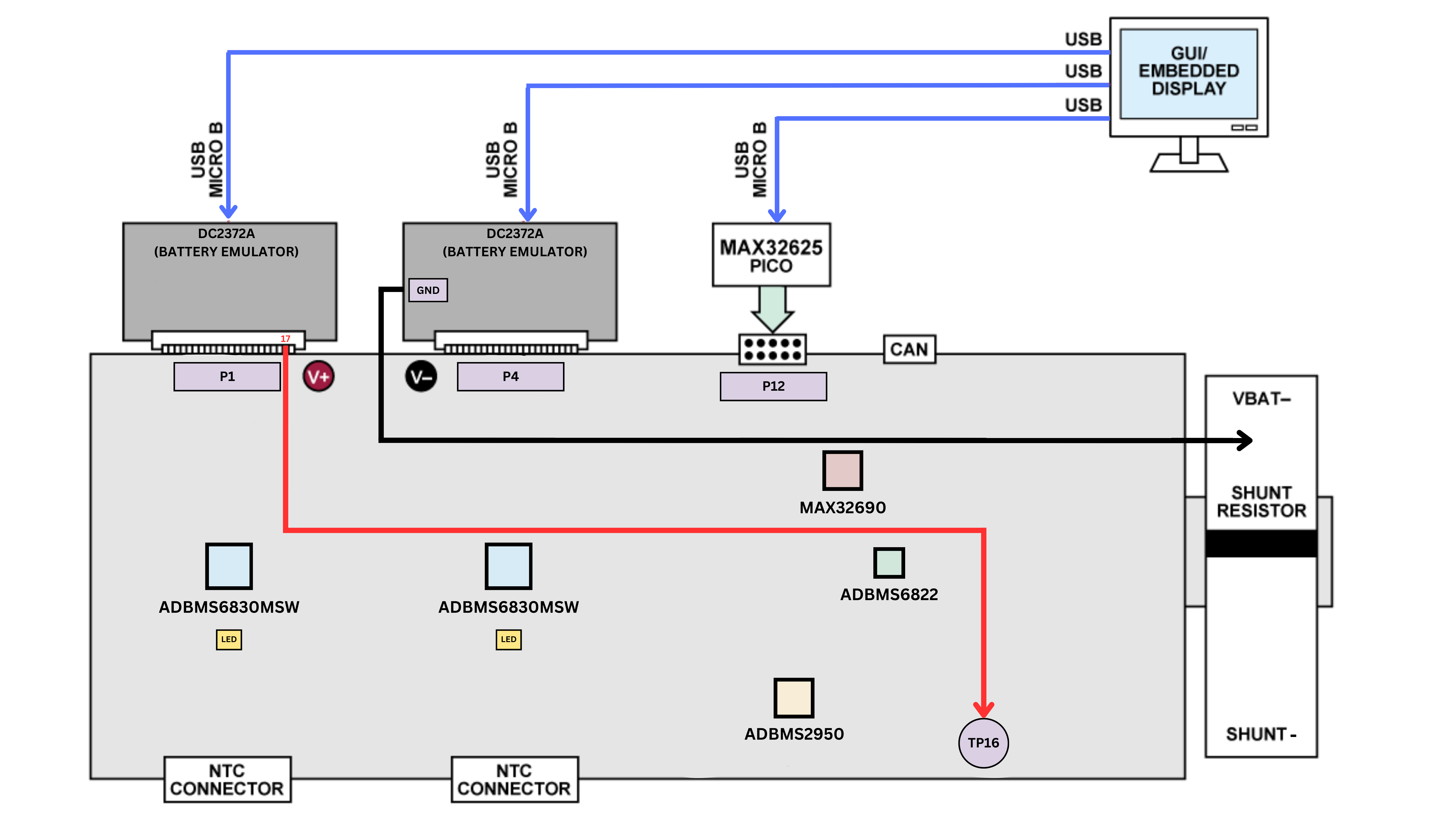

Follow the setup shown in the diagram below to get the board up and running. Ensure that the hardware parts and equipment are complete based on list of Equipment Needed. The banana plug cables used in this setup only have a maximum rating of 10A. Cables suitable for higher current rating must be used if the intended application operates at range higher than 10A. Note that the AD-BMSE2E3W-SL board can only accommodate up to 100A.

Equipment Needed

1x AD-BMSE2E3W-SL Board

2x DC2472A Battery Cell Emulator Boards

1x MAX32625PICO Programming Adapter with 10-pin SWD cable (loaded with firmware image)

2x Cell Connector Block (18-cell connector)

2x USB Type A to Micro-B cable

2x Stackable Banana Plug to Alligator Clip Cable (BU-P1166-12-2, Red)

1x Stackable Banana Plug to Alligator Clip Cable (BU-P1166-12-0, Black)

7x Top Mount Heatsink (to be installed for high current applications)

1x Laptop or PC running Windows 10

Warning

This reference design has not undergone compliant testing for EMI/ EMC standards for automotive. It is up for the user to do its qualification as the requirements vary depending on its end application or use cases.

All the products described on this page include ESD (electrostatic discharge) sensitive devices. Electrostatic charges as high as 4000V readily accumulate on the human body or test equipment and can discharge without detection. Although the boards feature ESD protection circuitry, permanent damage may occur on devices subjected to high-energy electrostatic discharges. Therefore, proper ESD precautions are recommended to avoid performance degradation or loss of functionality. This includes removing static charge on external equipment, cables, or antennas before connecting to the device.

Note

For high current applications requiring greater than 50 A, it is advisable to install a heat sink to protect the pre-charge, charge, and discharge MOSFETs from overheating.

The AD-BMSE2E3W-SL Kit has 7 available HEATSINK PIN-FIN W/TAPE (375424B00034G) easy-to-install, adhesive type, aluminum top mount heat sink than can be installed directly on top of the board.

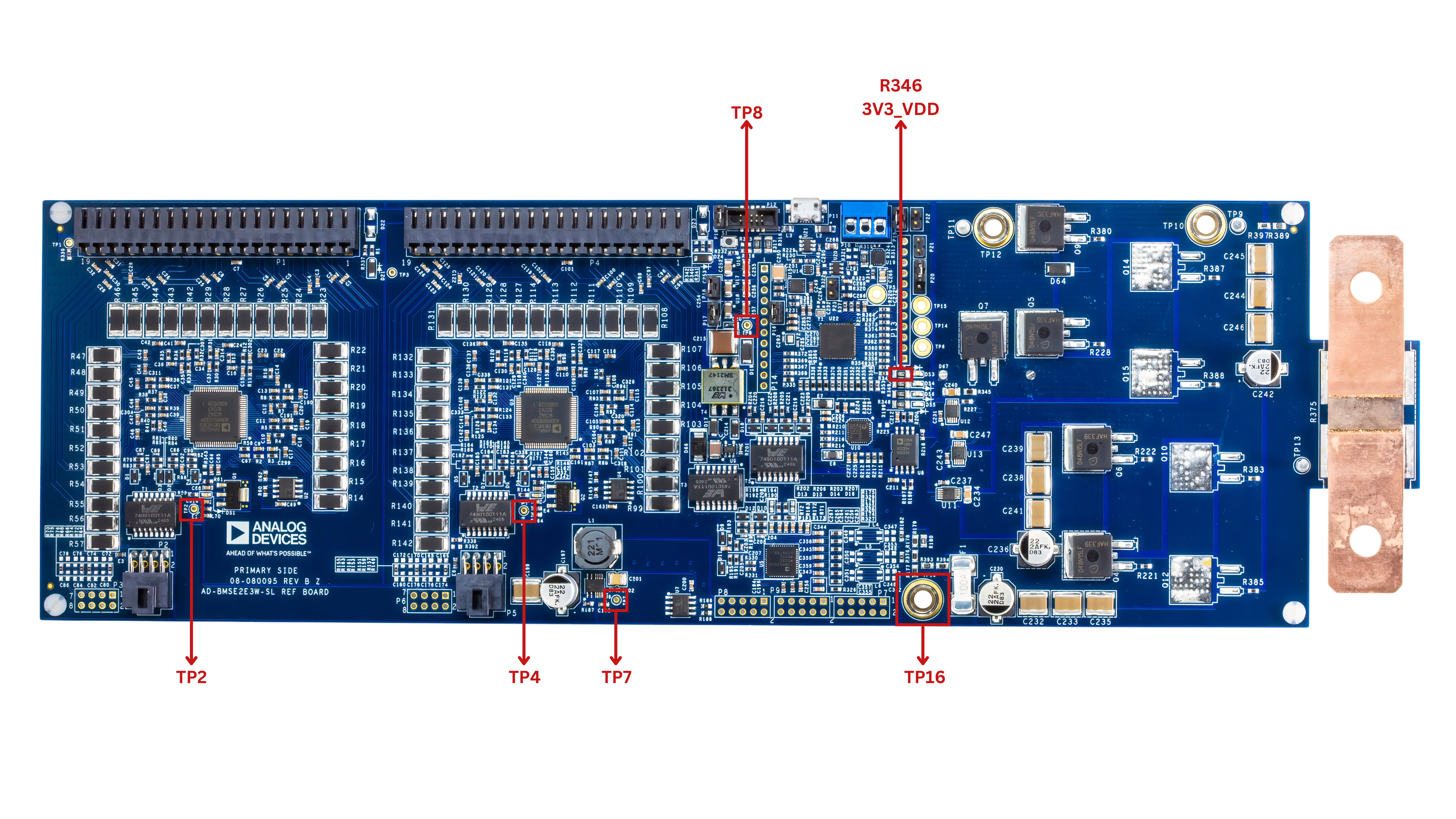

Peel off the protective film from the bottom of each heat sink and firmly press each one on top of the following FETs:

Attach the 5 heat sinks on the top layer of the board (Q4, Q5, Q6, Q7, and Q9),

the remaining 2 heat sinks on the bottom layer of the board (Q3 and Q8).

Preparing the MCU

By default (upon purchase), the AD+BMSE2E3W+SL board comes with a MAX32625PICO programmer adapter that is loaded with firmware image.

Otherwise, if you are using a new MAX32625PICO programmer (that is not part of the original kit), make sure to flash it first with the correct firmware image before connecting it to the AD-BMSE2E3W-SL board. If you do not know how to load the image, follow the instructions below:

Download the firmware image: MAX32625PICO Firmware Image for MAX32690

Do not connect the MAX32625PICO to the AD-BMSE2E3W-SL Board yet.

Connect the MAX32625PICO to the Host PC using the micro USB to USB cable.

Press the button on the MAX32625PICO. (Do not release the button until the MAINTENANCE drive is mounted)

Release the button once the MAINTENANCE drive is mounted.

Drag and drop (to the MAINTENANCE drive) the firmware image.

After a few seconds, the MAINTENANCE drive will disappear and be replaced by a drive named DAPLINK. This indicates that the process is complete, and the MAX32625PICO can now be used to flash the firmware of the AD-BMSE2E3W-SL Board.

Hardware Setup

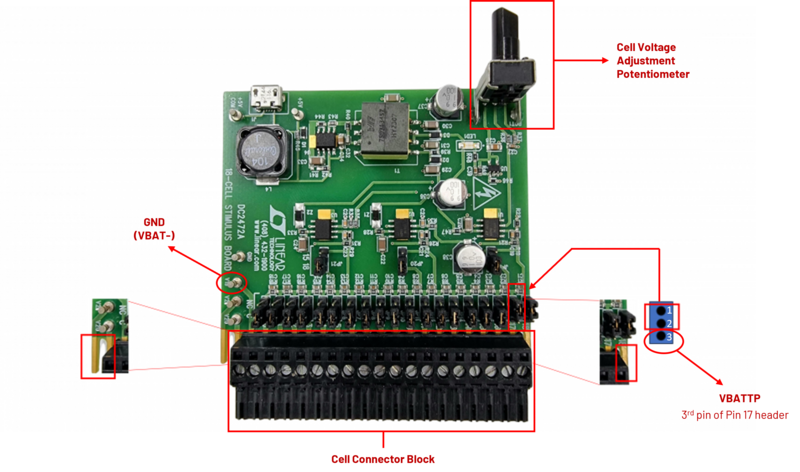

The board utilizes the DC2472A battery emulator as input for cell voltage measurement. The DC2472A allows a cell voltage of 1.4 V (min) to 4.2 V (max). Follow below steps to set up the board for cell measurement:

Screw the two cell connector blocks to the two DC2472A battery emulators. Note that the first two terminals and the last terminal of each DC2472A cell connector must be left hanging (refer to below figure). Make sure to also set the last two terminals’ input to low voltage or equivalent range of roughly 1.4V per cell.

Connect the DC2472A battery emulators to the ADBMSE2E3W-SL board through the cell connector blocks. Then, connect a micro-USB Type B cable to each DC2472A battery emulator and power the boards by connecting the other end of the cables to the Host PC.

Set the DC2472A battery emulators to the lowest voltage by fully turning the Cell Voltage Adjustment Potentiometer counterclockwise.

Attach the MAX32625PICO programmer to the AD-BMSE2E3W-SL board using the 10-pin ribbon SWD cable. Power the MAX32625PICO using a micro-USB to USB cable connected to the Host PC.

Connect the alligator clip cable (red) to the VBATTP Pin or the 3rd of Pin 17 header of the DC2472A battery emulator. Then, insert the other end of the cable (banana jack plug) to TP16 (VBAT+ terminal) of the AD-BMSE2E3W-SL board.

Figure 9 DC2472A’s VBATT+ Supply Connector to AD-BMSE2E3W-SL’s VBAT+ Terminal

Connect the alligator clip cable (black) to the GND (VBAT-) supply of the DC2472A battery emulator. Then, connect the other end of the cable to the Rsense (top side) of the AD-BMSE2E3W-SL.

Figure 10 DC2472A’s VBAT- Supply Connector to AD-BMSE2E3W-SL’s Rsense

Set the DC2472A battery emulators to HIGH voltage or equivalent to 4.1 V per cell by turning the Cell Voltage Adjustment Potentiometer clockwise.

Check the supply for the following test points as described in the diagram and table below. Make sure that the voltage levels are within the specified range.

Once all steps are completed, you are now ready to use this reference design and run the accompanying software found in the link below:

Note

The AD-BMSE2E3W-SL comes complete with firmware examples and easy-to-use application GUI. Access the software resources and see the setup procedure in the AD-BMSE2E3W-SL Software User Guide.

Resources

Design & Integration Files

Download

AD-BMSE2E3W-SL Design Support Package

Schematic

PCB Layout

Bill of Materials

Allegro Project

Guides&Sample Software

A software user-guide and sample application for AD-BMSE2E3W-SL are available:

Help and Support

For questions and more information, please visit the EngineerZone Support Community.